MUSTAD hooks are made using high-quality hi-carbon steel, which gives the hooks maximum strength. MUSTAD employs a unique tempering process to ensure consistent strength and high-quality hooks. Before tempering, the hooks are forged, which means that the hook wire is slightly compressed. This compression increases the strength of the hook by more than 30%!

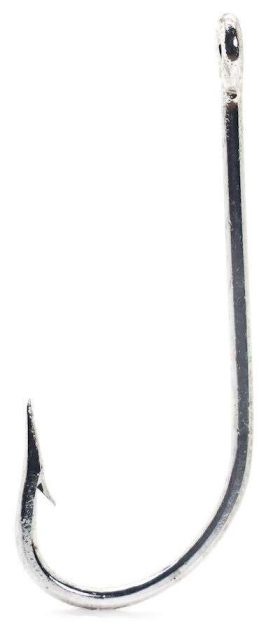

The Mustad O'Shaughnessy Hook – 3407 features a straight eye that is perpendicular to the hook plane. The shank, bend, point, and barb are all in the same plane without any offset, making it an ideal hook for trolled or retrieved lures. These hooks are forged, ringed, cadmium plated, and tinned. The durable material and excellent craftsmanship, from the strong shank to the razor sharp hook, ensure reliable performance.

FAQs

1. What is hi-carbon steel?

Hi-carbon steel is a type of steel that contains a higher amount of carbon than standard carbon steel. This extra carbon content improves the strength and hardness of the steel, making it ideal for applications that require toughness and durability, such as fishing hooks.

2. What is the tempering process used by MUSTAD?

The tempering process used by MUSTAD involves heating the hooks to a specific temperature and then cooling them rapidly. This process helps to align the molecular structure of the steel, making it stronger and more resistant to bending or breaking under pressure.

3. Why are the hooks forged?

Forging is a manufacturing process that involves shaping metal by applying compressive forces. By forging the hook wire, it becomes more compact and dense, resulting in increased strength and durability. Forged hooks are less likely to bend or break when subjected to stress during fishing.

4. What is the purpose of the ring on the hooks?

The ring on the hooks serves as an attachment point for various fishing tackle, such as swivels or leaders. It provides a secure connection between the hook and the fishing line, ensuring that the hook stays in place during the fishing process.

5. Why are the hooks cadmium plated and tinned?

Cadmium plating and tinning are additional coating processes applied to the hooks to enhance their corrosion resistance. These coatings help to protect the hooks from rusting when exposed to saltwater or freshwater environments, ensuring that they maintain their performance and longevity.

Jessia –

Justin –

Latrice –